Crafting Affordable Polycarbonate Sunglasses from Scratch

Style and affordability don't always go together, but iPOP Eyewear makes it happen. Curious about how those stylish sunglasses are created? It's a detailed process from raw materials to finished product. Here's how iPOP combines fashion, function, and budget-friendly prices.

The Essence of iPOP Eyewear

iPOP's mission is simple, great sunglasses for everyone without breaking the bank. Quality is a priority, but so is affordability. Every pair features sharp design and reliable protection. Whether you're strolling in the city or relaxing at the beach, iPOP provides UV protection with a stylish edge.

Raw Materials Selection

It all starts with choosing the right materials, polycarbonate is the top choice. It's tough, clear, and lightweight, a better option than glass. It won't shatter and ensures crisp vision.

We source high-quality polycarbonate from trusted suppliers. Every batch is thoroughly inspected to ensure no flaws. Once approved, it's ready to be transformed into sunglasses.

Lens Manufacturing

This is where the magic happens. Polycarbonate is crafted into lenses that block UV rays and feel great to wear. It's a blend of science and style.

Molding

Polycarbonate pellets are melted and injected into molds. The shapes and curves are tailored to each frame style, precision is key. A single mistake can throw it off, but when done right, the lenses are clear and comfortable.

Tinting and Coating

Next, lenses get their color, from subtle gradients to bold mirrors. This adds personality and reduces glare. A UV coating is applied too, keeping your eyes protected all day and making bright outdoor conditions easier to manage.

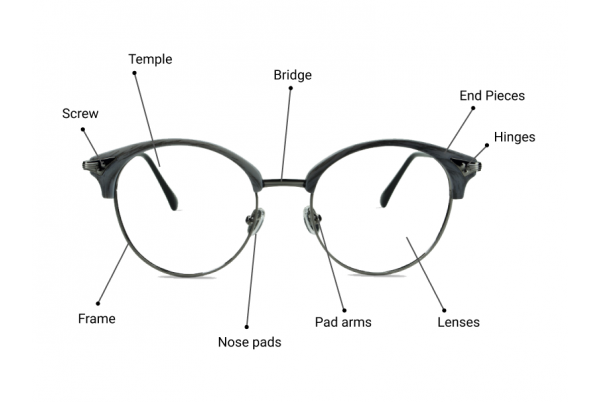

Frame and Temple Creation

With lenses complete, frames and arms are shaped. They define the sunglasses' look, whether classic aviators or sleek modern designs.

Cutting and Shaping

Heated plastic sheets are cut into frame designs. Every cut is precise, balancing style and comfort. A lightweight fit is essential, ensuring hours of wear feel good.

Assembly and Finishing

Frames are connected with hinges for smooth opening and closing. A final polish gives them a sleek finish. The result is sunglasses that combine style and durability.

Distribution and Delight

Once crafted, the sunglasses are shipped to you. iPOP partners with distributors and online platforms to make them widely available. Carefully packaged, they arrive in perfect condition, ready to become your new favorite accessory.

A Vision Beyond Boundaries

iPOP is about creativity and authenticity. Affordable style brings people together, and each pair reflects the care put into it. From material selection to final polish, it's a labor of love.

Learn more about how polarized lenses are made, for extra clarity on bright days.